|

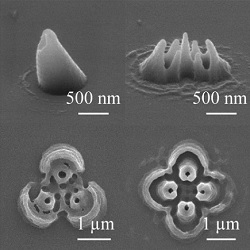

| Particles created using the 3-D printer--Courtesy of NC State |

Nanotechnology's effect on drug delivery is becoming more and more widespread with many projects around the globe dedicated to finding a way to bring it to the market. But once commercially available, nanomeds face another hurdle: manufacturing. Because the particles involved in these systems are so different in scale from other drugs on the market, drugmakers will need a way to make them in bulk and at a low cost, though still highly specific in form and function.

To that end, researchers at North Carolina State University have developed a technique for making 3-D structures at the nanoscale, offering repeatable production that is also relatively inexpensive. The technique was described in paper published on Dec. 8 in the journal Small.

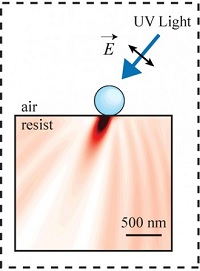

They made use of the centuries-old art of lithography, a printing method using oil and water. By shining a light through a transparent nanosphere and creating a sort of "fingerprint" for that particle, the researchers can control the size and shape of the resulting particles. Multiple beams of light can do this at a high volume.

"We are using the nanosphere to shape the pattern of light, which gives us the ability to shape the resulting nanostructure in three dimensions without using the expensive equipment required by conventional techniques," lead author Chih-Hao Chang said in a statement. "And it allows us to create 3-D structures all at once, without having to make layer after layer of 2-D patterns."

|

| Light shining through a nanoparticle to create a fingerprint--Courtesy of NC State |

In conventional 3-D printing of nanostructures, most techniques involve printing one layer at a time. This can get expensive and time-consuming, whereas making them all at once allows for a quicker process.

Ultimately, the light method could be used to make tiny structures for cancer drug delivery or nanoneedles for skin delivery in patches. What's important in all these delivery techniques is that the particles are uniform and predictable--which makes this method promising as a 3-D printer in the delivery arena.

"Our approach reduces the cost of nanolithography to the point where it could be done in your garage," Chang said.

- here's the NC State report

- get the research abstract