|

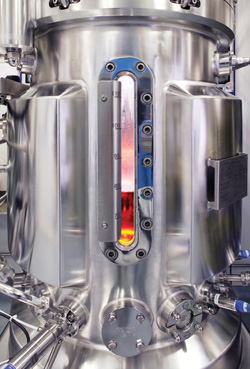

| Flu cell fermenter at a Novartis plant--Courtesy of Novartis |

With the effectiveness of this year's influenza vaccines so low as to have made most of this year's vaccinations pointless, the industry is searching for avenues to abbreviate the 6-month development and manufacturing process to deal better with the kinds of virus mutations that came into play this year.

Protein Sciences and Novartis ($NVS) have manufacturing plants approved that use a different manufacturing process that doesn't require the extended lead time, but most of the infrastructure is built around decades-old processes and unlikely to be quickly abandoned.

Other players using the older technology are not so hip on the idea of investing in newer technologies, saying things do work the way they are. "We've been doing this for 40-plus years and it has never failed us," David Greenberg, chief medical officer at Sanofi's ($SNY) vaccines division, told Bloomberg. "There's a lot to be said for a system that has never failed. If you're going to change, you have to make sure it is as reliable."

They established system didn't work well this year. The CDC reported that the flu vaccines in the U.S. were turning out to be only 23% effective. That is because a flu virus can mutate within 8 hours, and this year a strain did that after the parameters of the vaccines were approved, Bloomberg found. The mutation turned out to be particularly virulent, so has made this year's flu season particularly harsh. Even in years when the mutations are less a factor, the effectiveness of vaccines is only about 60%.

There may be other ways to shorten the process and improve effectiveness, but manufacturing and supply chain are prime targets for starters. That is because the traditional method takes months. The processes involves growing the virus in chicken eggs, then breaking the virus down and rendering it effective, but safe, and then getting tens of millions of doses manufactured.

A couple of companies have invested in faster processes. Protein Sciences makes its Flublok vaccine using technology that manufactures the proteins that provoke an immune response without first growing the entire virus. It was approved for all adults in October. CEO Manon Cox said his company expects in two years to be able to produce enough vaccine for the entire country.

The other faster manufacturing method grows the virus in cells instead of eggs. Novartis' influenza vaccine manufacturing plant in Holly Springs, NC, was approved in June to do that. In November 2012, the company received FDA approval for Flucelvax, which will be manufactured using the mammalian cell-culture system that will shave at least four weeks off the process, and perhaps more. It has a plant in Germany that has manufactured the vaccine using that technology. But it won't have them for long. In October the company agreed to sell the influenza vaccine making business, including its $1 billion plant in North Carolina, to Australia's CSL for $275 million. It is taking a $1.1 billion charge on the sale.

- read the Bloomberg story