|

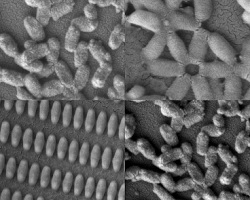

| Mass-produced nanoparticles of different shapes and sizes--Courtesy of MIT |

Researchers at the University of North Carolina at Chapel Hill and MIT have developed a way to quickly manufacture drug-delivering nanoparticles in various shapes and sizes with coatings that allow them many different functions.

Rather than the painstaking, hours-long nanoparticle process that involves repeatedly soaking the particles in coating solution, the MIT scientists sprayed the layers on top of them in just seconds. The process was developed in MIT's Hammond lab and is currently being commercialized by Svaya Nanotechnologies, according to an MIT report.

This, combined with UNC's PRINT (Particle Replication in Non-wetting Templates) technique, commercialized by Liquidia Technologies, allows for the mass-production of uniform nanoparticles with control over their shape and drug targets.

"The idea was to put these two industrial-scale processes together and create a sophisticated, beautifully coated nanoparticle, in the same way that bakeries glaze your favorite donut on the conveyor belt," said Paula Hammond of MIT. "Everyone's excited about nanomedicine's potential, and there are some systems that are making it out to market, but people are also concerned about how reproducible each batch is. That's especially crucial for applications such as cancer therapies."

The researchers tested the mass-produced nanoparticles on lab-grown breast cancer cells. The particles coated with hyaluronic acid using the new technique engulfed the cancer cells more efficiently than uncoated particles. They plan to further test the delivery vehicles for their effectiveness in shrinking tumors.

- here's the MIT report