|

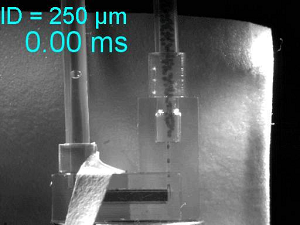

| Nanoparticles drop from a 3-D printed microfluidic channel at 250 micrometers in diameter--Courtesy of USC |

Nanotechnology, while still largely in preclinical stages for drug delivery, is thought to be on the cutting edge of the field as a means to develop highly specific, targeted and unobtrusive treatments. And as the research inches closer to commercialization, the manufacture of such particles will present a bottleneck for companies looking to make a dent if upscaling processes aren't already in place.

Researchers at the University of Southern California have developed a method to more fully automate the process of manufacturing nanoparticles. Currently, the process is mostly undertaken in smaller batches in a specialized lab, making the resulting particles thousands of times more expensive. For example, compared to pure, raw gold at about $50 per gram, gold nanoparticles cost around $80,000 per gram.

The USC team is now using microfluidics to make nanoparticles on a much larger scale. And with 3-D printed tubes that can manipulate droplets at 250 micrometers in diameter, they can produce the particles on a sort of assembly line. These are thought to be the smallest 3-D printed tubes in existence, according to the university.

Each tube can make millions of identical droplets, and unlike previous incarnations of a similar system, the pressure of each tube doesn't adversely affect that of its neighbors. In older systems, this was a fragile structure that could knock out the entire system with just a small change. But the USC team constructed theirs in a way that the junctions between tubes creates a uniform droplet and won't be affected by pressure changes.

They write in their study published in Nature Communications: "We apply this device in a parallel network to synthesize platinum nanoparticles using an ionic liquid solvent, demonstrate reproducible synthesis after recycling the ionic liquid, and double the reaction yield compared with an analogous batch synthesis."

- here's the USC release

- and here's the abstract